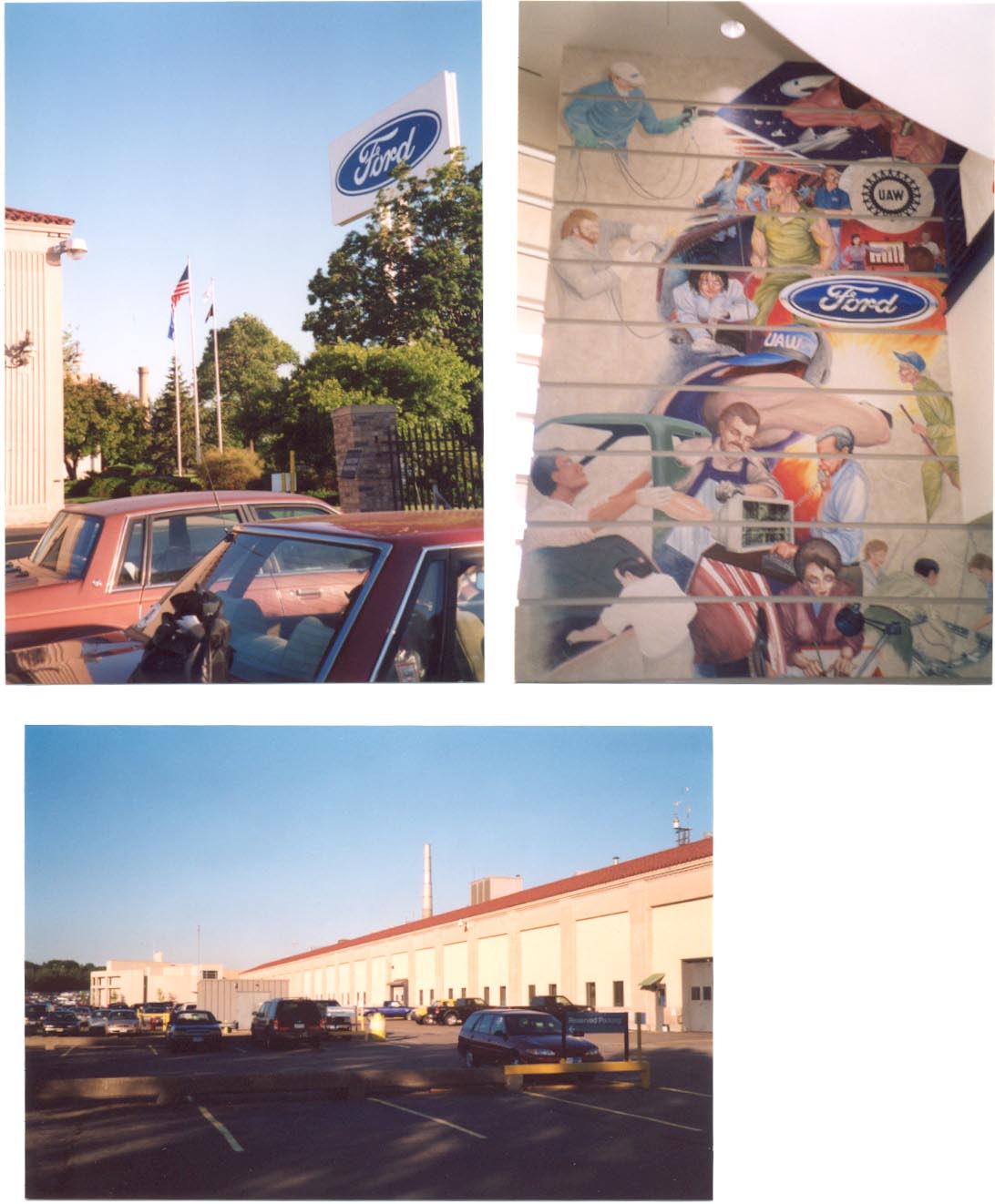

The Ford Motor Company has a Twin Cities Assembly Plant that assembles Ford Rangers. It is open for tours every Thursday evening, and closes for two weeks every summer. The plant also recently went on haitus because of the Firestone Tire recall. No tours are run when the plant is not operational; the tours are free. The tour starts in the theatre of a new rotunda built in conjunction with the Univerisity Of Minnesota Carlson School of Management. You will first see a 20-minute video on Ford and the assembly process, and then you will don protective glasses and enter into the Assembly Plant. The first thing you'll see are the brightly-colored, brand-new Rangers being started up (for the third time, the first two during tests) and driven out of the Driveaway Area to the huge parking Lot where they will be loaded on trailer or train car for the trip to their final destinations. There is a group of workers whose only job is to drive away these beautiful vehicles -- what a job!

The final assembly building was built in 1926, about the same time as the Rouge, covers 40 or more acres, 1 million or more square feet, with every area assigned to one activity or another, including pulling freight trains into the plant for delivery of parts. There are two levels to this assembly plant -- the upper is for the painting process, which takes about five hours. the lower level contains assembly lines for the frame and engine; eventually all meet up for installation of dashboard, seats, hoses, etc, utilizing many QA checks along the way. A robot holds up the windshield for adhesive to be placed, then sets it perfectly on the vehicle, late in the assembly process. Eventually, after numerous checks from the pits (beneath the line), rolling tests at 65 mph, hooked up to computers, the vehicles (in this case ranger trucks) are started up (for about the third time) and driven out to the lot, to be directed to the trailers that will carry them to their destinations.

It is curious that a researcher who has put forth a theory about a "Man from the Rouge "(Ford Motor Company River Rouge complex) laminating a new windshield for the Presidential Limousine at B building apparently didn't find a need to tour through an assembly plant prior to presenting this odd theory to the research community. (it may come as no surprise that this person has also put forth no documentation to date on any other aspect of this unusual theory, and refuses to acknowledge documentation put forth by anyone else that demonstrates this theory to be have such conflicts that the witness virtually impeaches himself). In its current status, this information is now part of the compendium MIDP, and unfortunately consists of little more than hearesay, speculation and innuendo and does not rise above the level of myth.

Are there any 'maintenance and repair' garages in an assembly building? Hardly. There are two areas where body touch-ups can be done and where corrections can be made, such as tightening loose hoses, etc; both of these areas are within the plant itself, and all activity is visible from all sides. Would this be a good place to stow an 8,000 lb vehicle for a clandestine windshield switch? Hardly; it is a three-ring circus.

An assembly plant is a union shop; the top executive is called the Plant Manager. The plant is part the Ford Division; Vice President for the Ford Division in 1963 was Lee Iacocca.